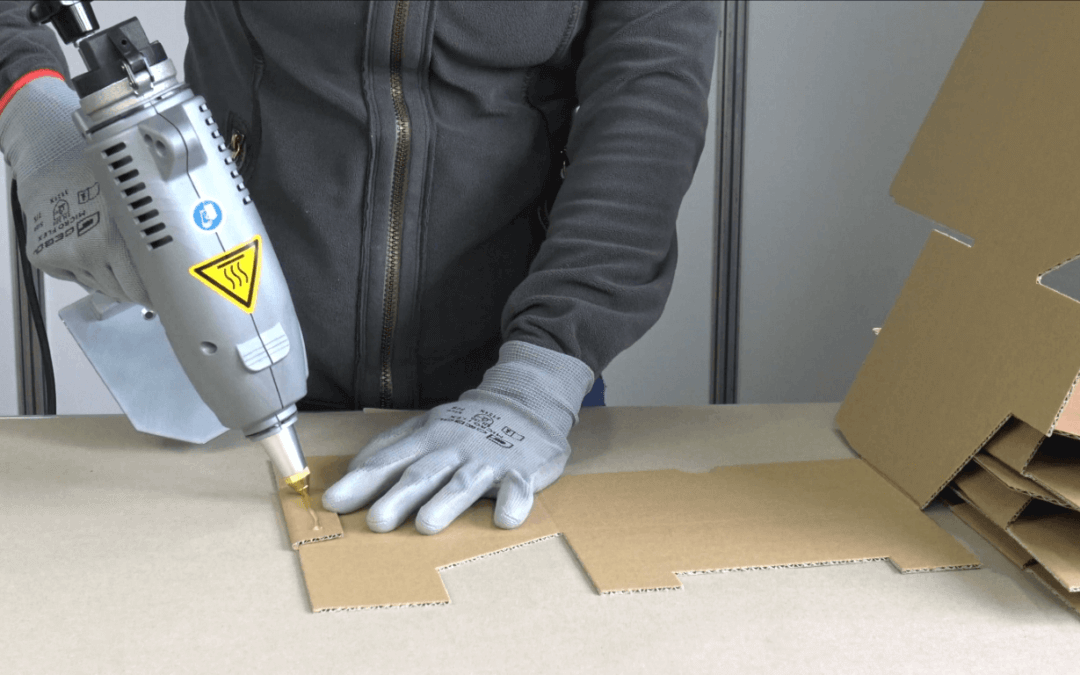

Applications are producing folding boxes, display production, labelling, sealing of outer packagings or shipping cartons and load securing just to name a few examples. The thermoplastic adhesive is processed with different application devices. Hand-guided glue guns, tank devices up to fully automated robot systems are used.

The wide range of applications and materials to be joined are met by a vast range of hotmelt adhesives with different properties. The selection of a suitable applicator and adhesive depends on the application at hand as well asoperational requirements and resources

Table of content

Your Advantages of hot-melt bonding

What you need to consider

Best Practice: Application

Check the problem solution

Do you have a gluing problem?

The hHot glue technique offers several advantages over other joining techniques - Click here to learn more!

- application possibilities adapted to the application (spray, dot, bead, film application)

- both permanent and removable bondings possible

- handling joined parts shortly after bonding because of quick setting of hotmelt adhesives

- no perforation of the materials to be joined, e.g. holes during stapling, which would favor tearing of the carton

- no risk of injury or damage to the product, e.g. due to metal clips sticking out)

- almost invisible joint (no bands or clips)

- packaging imprints are not covered or damaged

- no solvents, thus no special masks or suction measures at work station

- reduction of waste volume (e.g. no empty spray cans, unusable material residues)

When gluing bonding packaging, there are a few points things to consider - for examples please click!

- which materials are to be glued

- what is the surface condition (e.g. painted / coated)

- a specific temperature sensitivity must be taken into account (e.g. foams)

- what forces are to be expected

- the size of the surface to be bonded (desired application length and width)

- What type of bonding should be achieved? (e.g. final bonding, temporary fixing, sealing, insulation)

- exceptional thermal loads (e.g. very high or low temperatures during transport)

- are there requirements regarding the appearance of the bonded parts (colour of the adhesive, width of the glue joint etc.)

- the operational procedure and existing possibilities (e.g. compressed air connection available)

- specific requirements (e.g. in food or toy industry).

Application example: Energy balls in cellophane bags with cardboard hanger.

The gluing is done by applying an adhesive bead to the inside of the back and front flap of the cardboard hanger. After positioning the upper part of the cellophane bag between the cardboard flaps, they are pressed together.

A permanent bond is required. As this is a food packaging, an adhesive with respective FDA approval is mandatory, secure adhesion to cardboard and plastic (cellophane) is a must.

In addition, the bonding must be able to withstand the effects of cold and heat during transport. After assembly in the shop (hanging the confectionery bags on the shelf), the adhesive must withstand the weight of the confectionery bags.

“Hands-free working” when applying the adhesive is desirable to facilitate the positioning of the parts to be bonded.

The pneumatic glue gun TR 55 LCD is expanded with the suitable accessories for stationary working (deposit stand, stationary equipment, foot switch) and a 3-hole nozzle.

- The electronic temperature control of the TR 55 LCD is conveniently adjustable and regulates precisely. Low temperature oscillation protects the adhesive and ensures consistent results.

- With the 3-hole nozzle, three adhesive lines are laid side by side at the same time. This results in a larger adhesive surface without the disadvantage of a thick adhesive bead.

- The stationary setup enables “hands-free bonding”. The user can use both hands to align the components to be bonded correctly. The adhesive output is controlled by the foot switch.